ADC Hardware Average Funcion

This sample code guide is designed to help users easily and comprehensively understand ADC sample. This sample demonstrates how ADC samples data with hardware average function. This sample uses the hardware average function of the ADC peripheral to measure voltage on P0_1. ADC hardware average function can only be used in one shot mode and only schedule table 0 can be used. For RTL87x3E and RTL87x3EP, it is recommended to use the hardware average function.

Requirements

For hardware requirements, please refer to the Requirements.

Wiring

Connect P0_1 of EVB to an external DC voltage source. Input voltage of P0_1 must range from 0 to 3.3V.

Configurations

The entry function is as follows, call this function in main() to run this sample code. For more details, please refer to the Initialization.

adc_hw_average_demo();

Building and Downloading

For building and downloading, please refer to the Building and Downloading.

Experimental Verification

Press the Reset button on the EVB board, after initialization is complete, the ADC begins sampling. Once ADC sampling is finished, the converted voltage values will be printed in Debug Analyzer.

adc_handler: result xxx

Code Overview

This section introduces the code and process description for initialization and corresponding function implementation in the sample.

Note

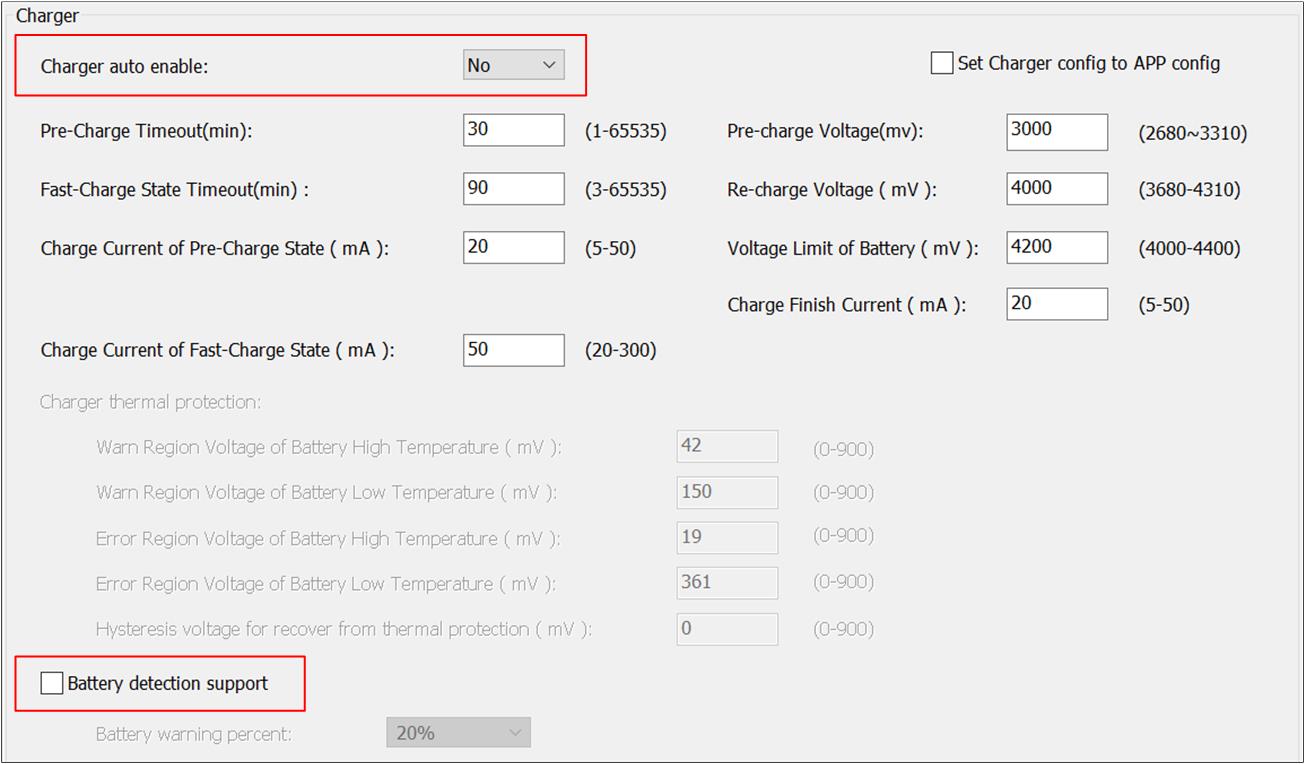

To use the mode, please turn off Charger auto enable and Battery detection support on the MCUConfig Tool. As shown in Turn Off Charger on the MCUConfig Tool.

Turn Off Charger on the MCUConfig Tool

Source Code Directory

For project directory, please refer to Source Code Directory.

Source code directory:

sdk\src\sample\io_demo\adc\adc_hw_average\adc_hw_average_demo.c.

Initialization

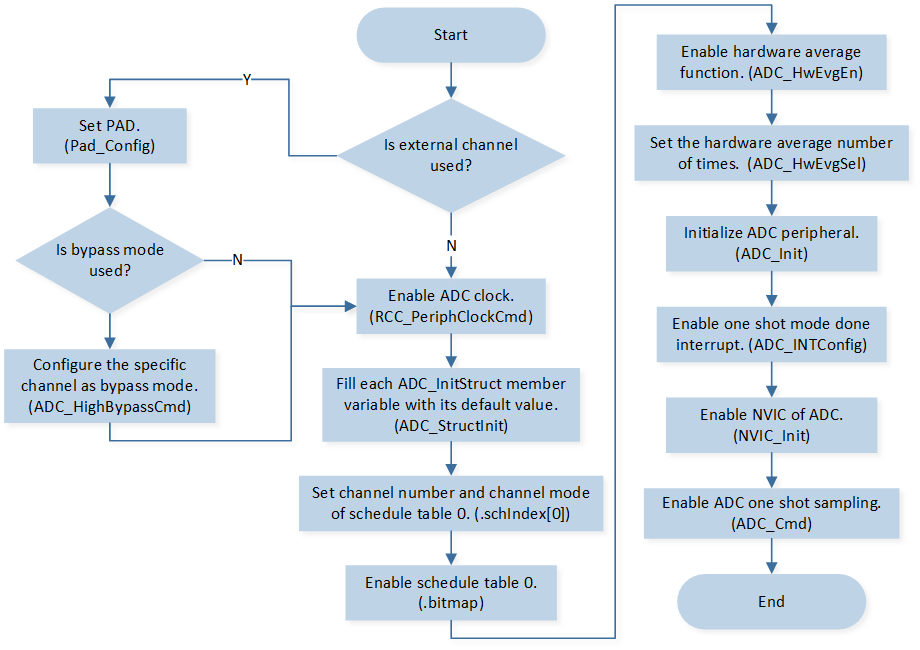

The initialization flow for peripherals can refer to Initialization Flow.

The initialization flow of ADC sampling in one shot mode by hardware average is shown in the following figure.

ADC One Shot Sampling by Hardware Average

-

Call

Pad_Config()andPinmux_Config()to initialize the pin.static void board_adc_init(void) { Pad_Config(ADC_1, PAD_SW_MODE, PAD_IS_PWRON, PAD_PULL_NONE, PAD_OUT_DISABLE, PAD_OUT_LOW); Pinmux_Config(ADC_1, IDLE_MODE); }

Call

RCC_PeriphClockCmd()to enable the ADC clock and function.-

Initialize the ADC peripheral:

Define the

ADC_InitTypeDeftypeadc_init_struct, and callADC_StructInit()to pre-filladc_init_structwith default values.Modify the

adc_init_structparameters as needed. The ADC initialization parameter configuration is shown in the table below.Call

ADC_Init()to initialize the ADC peripheral.

ADC Initialization Parameters ADC Hardware Parameters

Setting in the

adc_init_structVariablesADC

Bit Map

0x01

Schedule Index

Index 0 is set to

EXT_SINGLE_ENDED(1). Call

ADC_HwEvgEn()to enable hardware average function.Call

ADC_HwEvgSel()to set the hardware average times.Call

ADC_INTConfig()to enable ADC one shot mode done interrupt.Call

NVIC_Init()to enable NVIC of ADC.Call

ADC_Cmd()to enable ADC one shot sampling.

Functional Implementation

Interrupt Handle

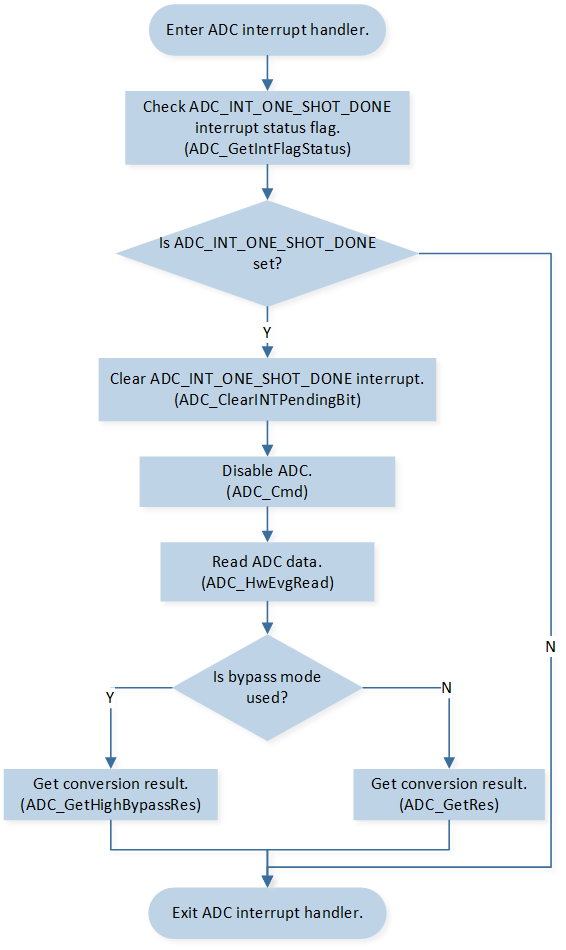

When ADC sampling is completed, ADC one shot mode end interrupt is triggered and enters the interrupt handler. ADC interrupt handle flow is shown in the following figure.

ADC Interrupt Handle Flow

Call

ADC_GetIntFlagStatus()to checkADC_INT_ONE_SHOT_DONEinterrupt status.Call

ADC_ClearINTPendingBit()to clearADC_INT_ONE_SHOT_DONEinterrupt.Call

ADC_Cmd()to disable ADC.Call

ADC_HwEvgRead()to read ADC raw data.Call

ADC_GetRes()to get conversion result.